Leading Manufactures of

About us

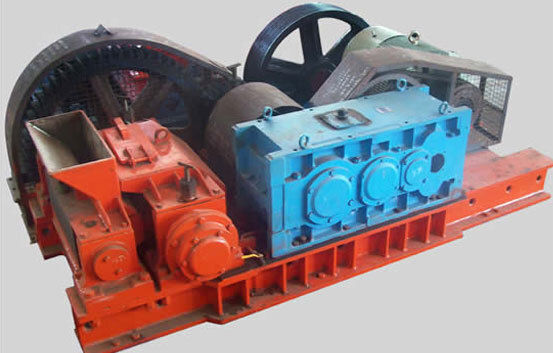

Ecoman is one of the leading manufacturers of cullet crusher and slag crushing plant equipments.

Since 1982 we have been the leading manufacturer and OEM supplier for Sponge Iron Plant, Power Plant, Cement Plant, Quartz Plant, Dolomite Plant and a host of other types of minerals plants. Among the various plants, one of our specialties has been the manufacturing of slag crushing plant. Our years of expertise and experience has led us to manufacture a fleet of crushing, grinding and screening products that are used to ensure slag is processed at extremely high efficiency while ensuring low costs. Our slag crushing plant is known for their precision based engineering and is widely utilized for crushing refractory’s, stone, slag, coal and a host of other products. We completely assure our clients of offering slag crushing plant equipment that is known for its high quality, precision and accuracy and long term reliability. We also offer complete support in regard to installation, automation and instrumentation services.

Leading Manufactures of

Screens

Leading Manufactures of

Feeders

Leading Manufactures of

SPMs Special Purpose Machines

Our Clients

Why Us?

Customers from mining, quarrying, construction, and manufacturing industries have praised our work. Our array of machines plays a significant role in the processing, handling, and transportation of various materials. Apart from our product range, the following factors attributed to client appreciation.

QUALITY ASSURANCE

The quality and top-class performance of our machines have been our top priority since the beginning.

Infrastructure

Due to our modern infrastructure, we are able to design & develop machines of top quality in accordance with market demand.

Clientele

In the industry, we cater to the demands of the most distinguished clients with our top-of-the-line crushers, impactors, and other machines.